Main motorSiemens(Germany) ,Brook(UK) ,GE(USA)

Suitable materialsHDPE, LDPE, LLDPE

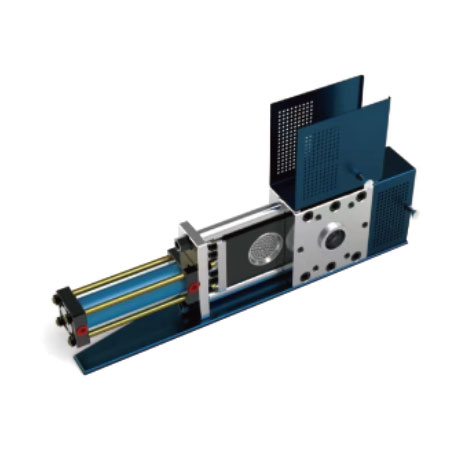

Screw L/D32:1/30:1

InverterSchneider(French), ABB(Switzerland)

Temperature-controlled meterOmron

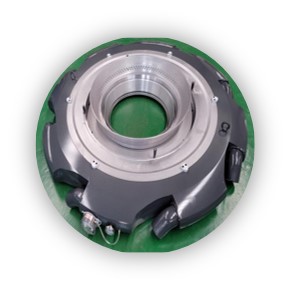

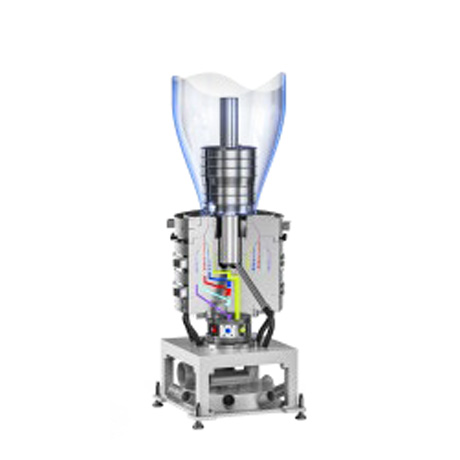

Air ringDouble vent air ring

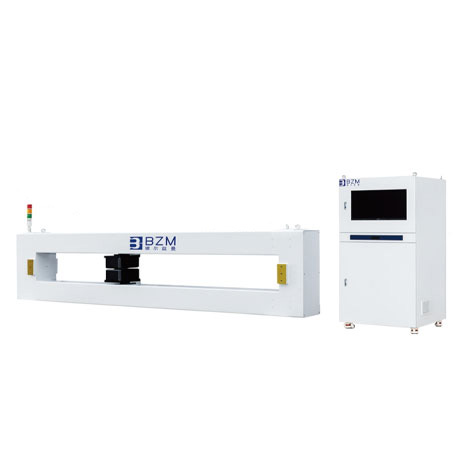

Automatically complete film winding and roll changing according to user settings.Torque motor to control the film rewinding speed and tightness, to make the film rewinding flat.Friction type single winding.Expansion force module: Torque motor control.Air sharft: With a flattening roller to make the film even

Provides rotational driving force for the die head to evenly distribute the extruded raw materials.Raw material NO.40 Steel.Composed by die core, die body , die ring and heating ring.Forging and heat treating, much higher strength and toughness than normal type die head.Machining center is from Taiwan, so the die head is higher accuracy.Keep Film thickness average and equal , and film quality is shining.Custom produce, according to different type raw material , supply different design die head.

Rapidly reduce the temperature, improve production efficiency and glossiness, reduce the friction coefficient, make the tension uniform and ensure stable traction.

Product Specifications

| MODEL | CX-1300 | CX-1600 | CX-2100 | |

| Suitable materials | HDPE, LDPE, LLDPE | HDPE, LDPE, LLDPE | HDPE, LDPE, LLDPE | |

| Film width | 800-1200mm | 1000-1500mm | 1200-2000mm | |

| Film thickness | 0.006-0.10mm | 0.006-0.10mm | 0.006-0.10mm | |

| Max.extrusion output | HDPE | 100kg | 120kg | 150kg |

| LDPE | 150kg | 180kg | 200kg | |

| Screw diameter | 65mm | 70mm | 80mm | |

| Screw L/D | 32:1/30:1 | 32:1/30:1 | 32:1/30:1 | |

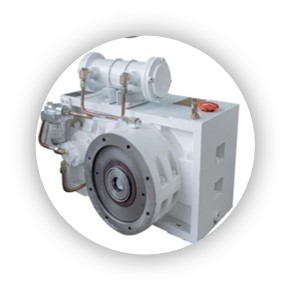

| Gearbox | 200 | 200 | 250 | |

| Main motor | 30kw | 37kw | 45kw | |

| Air blower | 5.5kw | 7.5kw | 11kw | |

| Average power consumption | 30kw | 40kw | 50kw | |

| Die diameter | HDPE | 120mm | 300mm | 500mm |

| LDPE | 250mm | 350mm | 500mm | |

| Traction roller width | 1300mm | 1600mm | 2100mm | |

| Dimension/Weight | 6*3.5*6.5m/5.5T | 6*4*7.5m/7T | 7*4.5*9.5m/8.5T | |

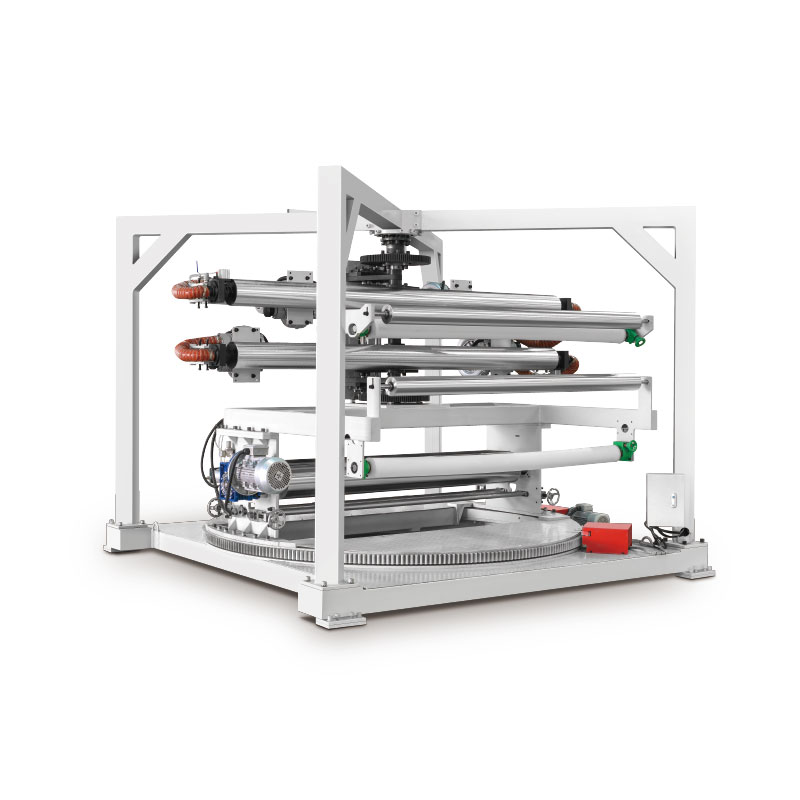

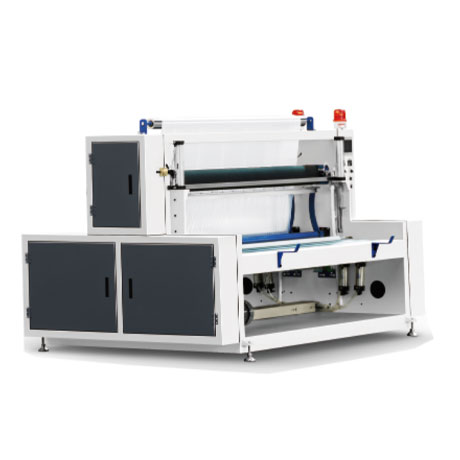

In the packaging manufacturing industry, precision and speed are the keys to success, and our single-layer high-speed blown film machine is perfectly tailored to meet these stringent requirements. Designed specifically for seasoned and professional packaging manufacturers, this high-performance machine seamlessly combines precision with high production capacity, bringing breakthrough performance to your production line.

The real-life image of the high-speed blown film machine featured here was custom-made for a client from the United States, who boasts over 30 years of experience in the packaging field. With extensive knowledge of blown film machine characteristics and performance from countries worldwide, they found that while Italian and German machines had good high-speed performance, their prices were considerably high. Furthermore, there were concerns about purchasing Chinese machines, fearing insufficient after-sales support and product performance. Eventually, through a friend's recommendation, they discovered that our SuperTrust Mechanical Technology perfectly matched their requirements. Our machine's performance is on par with European counterparts, with excellent after-sales service, and yet, it is substantially more cost-effective.

Our high-speed blown film machine is equipped with advanced technology, enabling outstanding microweight control, coupled with rotating die heads and rotating air rings. This means that you can achieve high-precision material blending without sacrificing production speed. Regardless of how stringent your product requirements are, our machine ensures the uniformity and consistency of each film roll, meeting your high demands.

Not only does our high-speed blown film machine excel in precision, but it also stands out with impressive high production capacity. Its design and engineering have been meticulously optimized to produce more film in the shortest possible time. This means you can meet orders in less time, enhance production efficiency, and maximize your profits.

Our machine not only boasts excellent performance but also exceptional reliability. It incorporates advanced technology and materials to ensure long-term stable operation, reducing downtime and maintenance costs. You can confidently rely on this machine to provide continuous support to your production.

Whether you are manufacturing food packaging, medical film, or other high-demand applications, our high-speed blown film machine can meet your requirements. Its versatility and flexibility make it suitable for various industries and applications, providing you with outstanding solutions.

If you are a seasoned and professional packaging manufacturer in need of equipment upgrades, our single-layer high-speed blown film machine will become your indispensable partner. It will help you achieve higher precision, faster speeds, and increased productivity, allowing you to stand out in a fiercely competitive market. Choose innovation, choose the high-speed blown film machine, and elevate your production to an entirely new level.

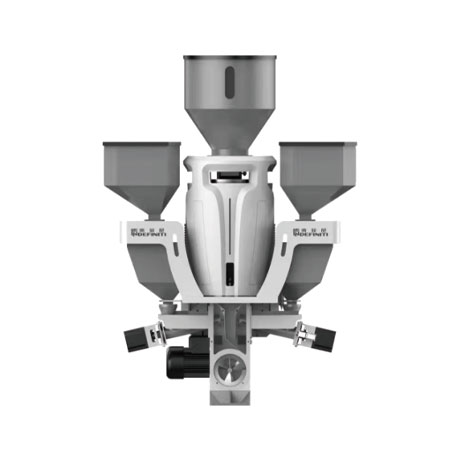

Optimized screw raises the extrusion volume and using lifespan. Higher anti-corrupt and anti-grind ability.

The motor operates with frequency conversion, which shows its advantages in terms of energy saving.

The up-traction determines the Traction stability, plastic film flatness and embossing effect.

Chaoxin brand Unique

The thick frame makes the machine more durable and reliable.

External circulation oil cooling system and hard tooth ensures the high working speed and lifespan of the gear joint.

Advanced heating is much better in terms of life, heating speed and heat preservation effect than stainless steel heating.

The structurally optimized high-speed air ring reduces the wind resistance and make the change of wind volume gentle.

Chaoxin creates a precedent of guarantee period in this industry, which enables clients to get trully hassle-free products & sevice.

5S management standards and high-end machining center equip Chaoxin with precision production capabilities and ensure product standards and quality.

ZHEJIANG CHAOXIN MACHINERY TECHNOLOGY CO., LTD.

Booth No:28B58

Time: January 27 - 30, 2026

Exhibition Hall Name:CROCUS EXPO International Exhibition Center

Add:Mezhdunarodnaya str. 16, 18, 20, Krasnogorsk, Moscow region, Russia

WEB: www.zjchaoxin.com