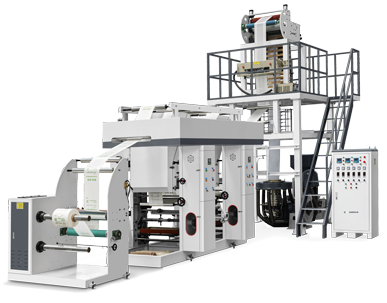

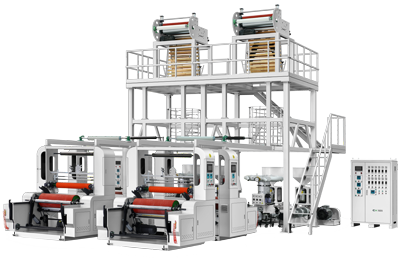

Excellent equipment: Chaoxin adopts the industry's first five-roller traction, has multiple winding mode patents, and uses internationally renowned brands ABB, Omron, and Schneider for assembly.

Independent research and development: Chaoxin's extruder adopts self-developed 30:1 and 32:1 ultra-high-speed double alloy screws, and is equipped with motors from internationally renowned brands GE, Siemens, and Brook.

Warranty service: Chaoxin sets an industry precedent by providing a 3-year warranty on the core components of the blown film machine.

Energy saving : Chaoxin focus on energy saving and environmental protection, and reduce energy consumption and waste generation through precise control systems and optimized processes.