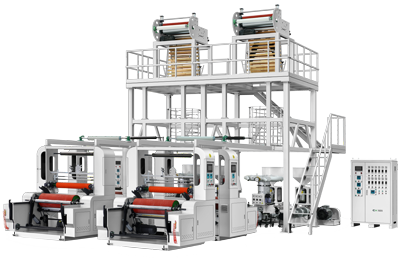

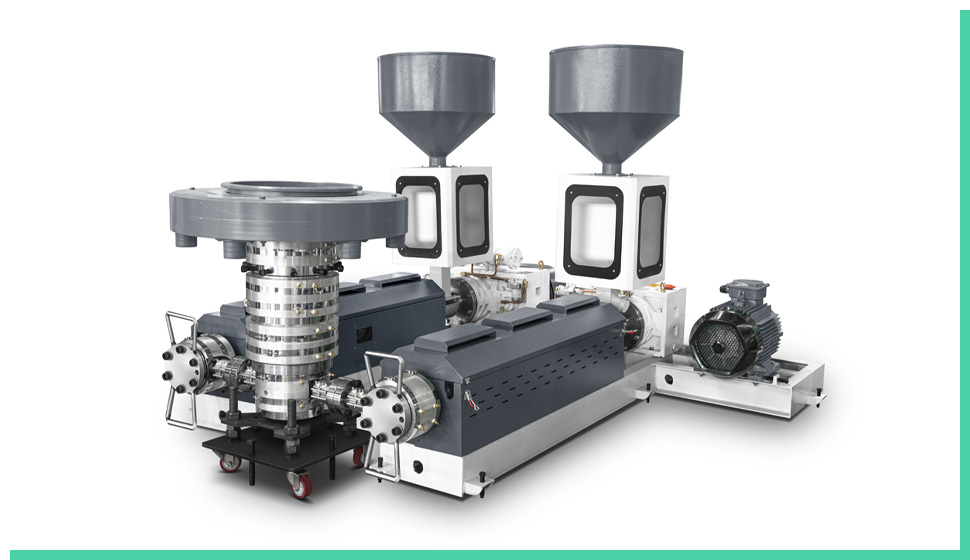

Energy efficient: Reduce costs, save resources while ensuring the stretchability and uniformity of the film

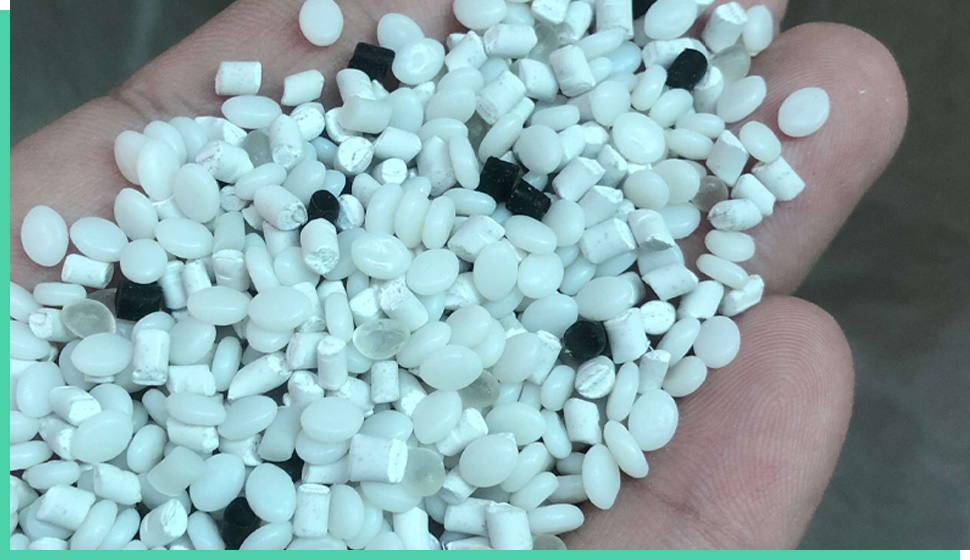

Saving raw materials: Through the design of the ABA structure, recycled materials can be used in the center layer.

A layer material: Generally reinforced materials or functional materials, which give the film more functionality and application advantages.

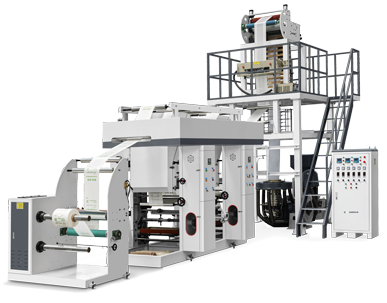

High production efficiency: Multiple layers of film can be extruded at the same time to improve production efficiency.