ZHEJIANG CHAOXIN MACHINERY TECHNOLOGY CO..LTD

Organizer: esse Düsseldorf GmbH

Mailing Address: P.O. Box 10 10 06, D-40001 Düsseldorf, Germany

Venue Address:Stockumer Kirchstraße 61, D-40474 Düsseldorf, Germany

ZHEJIANG CHAOXIN MACHINERY TECHNOLOGY CO..LTD

Organizer: esse Düsseldorf GmbH

Mailing Address: P.O. Box 10 10 06, D-40001 Düsseldorf, Germany

Venue Address:Stockumer Kirchstraße 61, D-40474 Düsseldorf, Germany

Main motorSiemens(Germany) ,Brook(UK) ,GE(USA)

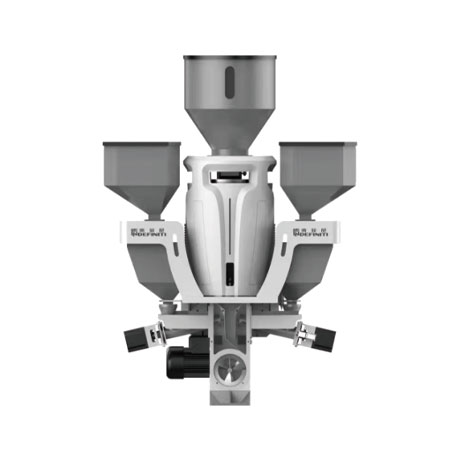

Suitable materialsPBAT, PLA +MD/ST

Screw L/D32:1

InverterSchneider(French), ABB(Switzerland)

Temperature-controlled meterOmron

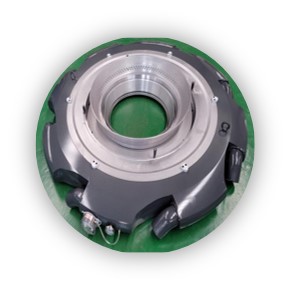

Air ringThree vent air ring

Product Specifications

| MODEL:Twin Head Series | CX-600 | CX-800 | CX-1000 | |

| Suitable materials | HDPE, LDPE, LLDPE | HDPE, LDPE, LLDPE | HDPE, LDPE, LLDPE | |

| Film width | 100-500mm | 300-700mm | 400-900mm | |

| Film thickness | 0.01-0.15mm | 0.01-0.15mm | 0.01-0.15mm | |

| Max.extrusion output | HDPE | 80kg | 100kg | 120kg |

| LDPE | 160kg | 180kg | 200kg | |

| Screw diameter | 55mm | 60mm | 65mm | |

| Screw L/D | 32:1/30:1 | 32:1/30:1 | 32:1/30:1 | |

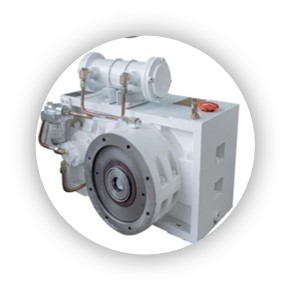

| Gearbox | 180 | 180 | 200 | |

| Main motor | 30kw | 37kw | 45kw | |

| Air blower | 5.5kw | 5.5kw | 5.5kw | |

| Average power consumption | 35kw | 45kw | 55kw | |

| Die diameter | HDPE | 50mm | 80mm | 100mm |

| LDPE | 100mm | 150mm | 200mm | |

| Traction roller width | 600mm | 800mm | 1000mm | |

| Dimension/Weight | 5.5*7*5.2m/6T | 5.5*7.5*5.2m/6.5T | 5.5*8*6m/7T | |

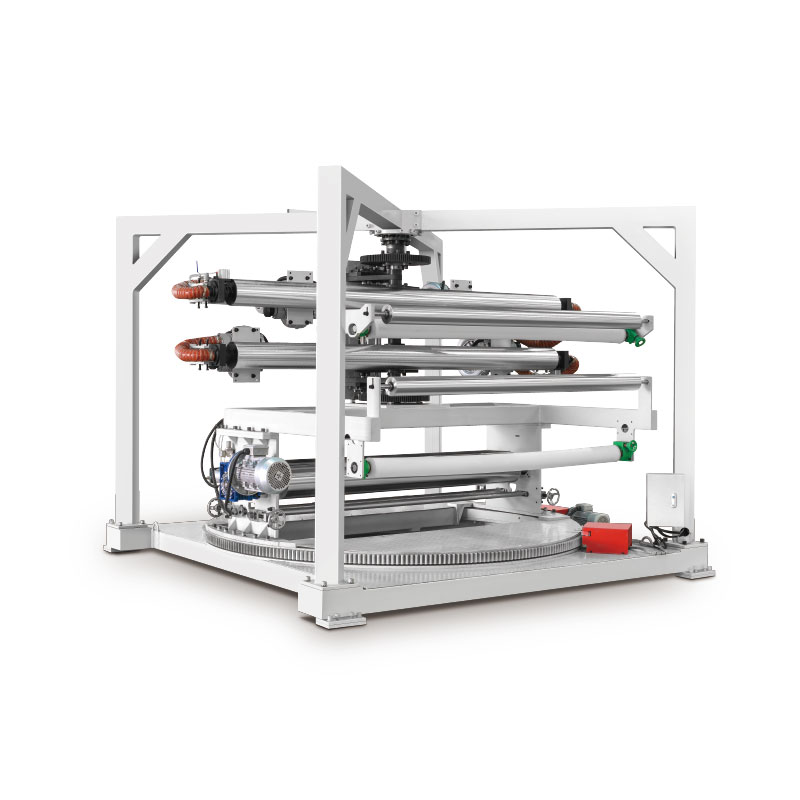

In the field of plastic film production, the single screw double die-head blown film machine occupies an important position. With the continuous growth of the demand for plastic products, the blown film machine, as a key equipment, its performance and advantages directly affect the quality and production efficiency of plastic films. The single screw double die-head blown film machine stands out among many blown film equipments with its unique design and excellent performance, and has become the first choice of many plastic film production enterprises. The emergence of the single screw double die-head blown film machine has brought new opportunities and challenges to the production of plastic films. It not only improves the production efficiency and reduces the production cost, but also brings more market competitiveness to enterprises.

The single screw double die-head blown film machine adopts the design of one extruder equipped with two die-heads, which greatly improves the output. This design can produce more plastic films in the same time and meet the needs of large-scale production. For example, the single screw double die-head blown film machine of Zhejiang Chaoxin Machinery Technology Co., Ltd. is scientifically designed with one extruder and two die-heads, which improves the output. It has the advantages of high speed, low consumption and energy saving. At the same time, as mentioned in the patent of the manufacturing method of the extrusion double die-head mechanism of the plastic blown film machine, the double die-head extrusion mechanism doubles the output during operation and saves 20% of electricity compared with two plastic blown film machines.

The screw and barrel of the single screw double die-head blown film machine are made of alloy steel, nitrided and precision machined. This treatment method makes the screw and barrel have the characteristics of high hardness and strong corrosion resistance, and is durable. The barrel and screw of the extruder are made of high-quality alloy steel, nitrided and precision machined, with hardness and corrosion resistance.

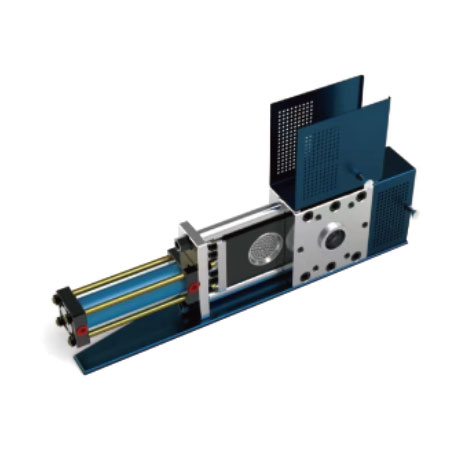

The die-head structure and air cooling device of the single screw double die-head blown film machine can ensure that the extruded molten material is uniform and the blown film has good smoothness. The die-head is hard chrome plated, and its structure is spiral mandrel type, so the extruded molten material is uniform; the air cooling device structure is labyrinth type, and the air output is uniform, so the blown film has good smoothness.

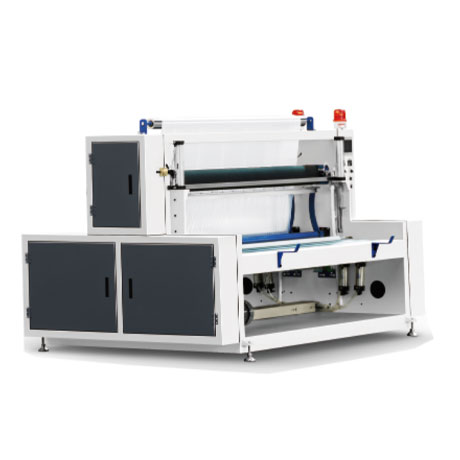

The winding device of the single screw double die-head blown-film machine adopts pressure friction winding or center winding, and the torque motor adjustment brings the advantages of flat winding and convenient roll change. It adopts pressure friction winding or center winding, and uses torque motor adjustment, with flat winding and convenient roll change. In the winding device of the blown film machine, a crane mechanism is installed at the upper end of the machine body. When the winding roll starts to wind the plastic film on the pressure arm, only the next receiving roll needs to be manually placed on the discharging arm, and the crane mechanism hooks the receiving roll through the hook, and transfers it to the hook plate of the placing mechanism for standby replacement with the cooperation of the air cylinder and reducer. The whole process is simple and fast, and the receiving roll can be transported to the placing mechanism without many people, thus saving manpower.

The single screw double die-head blown film machine has the remarkable characteristics of high output and low consumption, realizes efficient utilization in energy, labor and production plant, and thus greatly reduces the production cost. Its unique design, with one extruder equipped with two die-heads, greatly improves the output. For example, the blown film machine designed and produced by Zhejiang Chaoxin Machinery Technology Co., Ltd. has increased the production volume through scientific design. In terms of energy, the power part saves the excess energy consumption of the motor by using a frequency converter. For example, the motor actually only needs 30Hz to generate sufficient power in production, and the excess energy is no longer wasted. The heating part adopts an electromagnetic heater, and the energy saving rate is about 30% - 70% of that of the old resistance coil. It has the advantages of fast heating speed, reduced heat transfer heat loss, improved production efficiency, and increased insulation layer to improve the heat energy utilization rate. In terms of labor, the equipment has a high degree of automation and reduces the demand for manual operation. At the same time, its compact design also saves the space of the production plant and reduces the site cost for enterprises.

The single screw double die-head blown film machine can be used to blow a variety of plastic films and has a wide range of application fields. It can blow plastic films such as LDPE, HDPE, LLDPE, etc. These films are widely used in many fields such as food, clothing, textile, industry, etc., and can be made into various vest bags, flat bags, etc. The films blown by the blown film machine of Zhejiang Chaoxin Machinery Technology Co., Ltd. can cover all the above application fields.

The single screw double die-head blown film machine shows great value and broad prospects in the field of plastic film production with its many outstanding advantages.

Firstly, it has the characteristic of high-efficiency output. The design of one extruder equipped with two die-heads greatly improves the output, meets the needs of large-scale production, and brings higher economic benefits to enterprises.

Secondly, it is made of high-quality materials to ensure the durability of the equipment. The screw and barrel are made of alloy steel, nitrided and precision machined, with high hardness and strong corrosion resistance, reducing the maintenance cost and replacement frequency of the equipment.

Furthermore, the film quality is good. The die-head structure and air cooling device ensure that the extruded molten material is uniform and the blown film has good smoothness, improving the market competitiveness of the product.

Convenient winding is also one of its major advantages. The winding device adopts pressure friction winding or center winding, and the torque motor adjustment brings the advantages of flat winding and convenient roll change, improving the production efficiency.

In terms of advantages, the single screw double die-head blown film machine saves energy and cost. The characteristics of high output and low consumption enable it to realize efficient utilization in energy, labor and production plant, reducing the production cost. The power part adopts a frequency converter, and the heating part adopts an electromagnetic heater, with remarkable energy-saving effect. At the same time, it has a high degree of automation, reduces the demand for manual operation, and its compact design also saves the space of the production plant.

Its wide applicability enables it to be used to blow a variety of plastic films to meet the needs of different fields. It can blow plastic films such as HDPE/LDPE/LLDPE, and is widely used in many fields such as food, clothing, textile, industry, etc., with broad market prospects.

Advanced technology and exported overseas. Chaoxin Machinery continuously improves and innovates the single screw double die-head blown film machine, making its products exported to many countries and regions due to advanced technology and excellent quality, and enhancing the influence of Chinese blown film machines in the international market. The single screw double die-head blown film machine has irreplaceable advantages in the field of plastic film production.

Optimized screw raises the extrusion volume and using lifespan. Higher anti-corrupt and anti-grind ability.

The motor operates with frequency conversion, which shows its advantages in terms of energy saving.

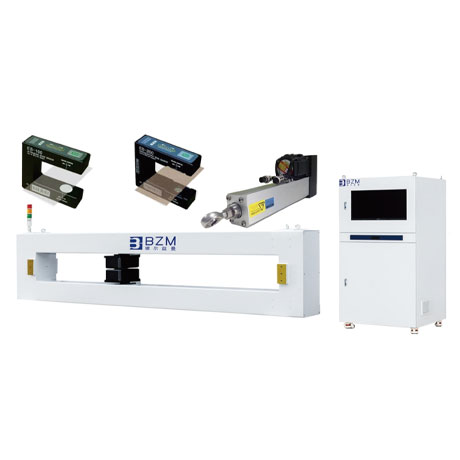

The up-traction determines the Traction stability, plastic film flatness and embossing effect.

The thick frame makes the machine more durable and reliable.

External circulation oil cooling system and hard tooth ensures the high working speed and lifespan of the gear joint.

Advanced heating is much better in terms of life, heating speed and heat preservation effect than stainless steel heating.

The structurally optimized high-speed air ring reduces the wind resistance and make the change of wind volume gentle.

Chaoxin creates a precedent of guarantee period in this industry, which enables clients to get trully hassle-free products & sevice.

5S management standards and high-end machining center equip Chaoxin with precision production capabilities and ensure product standards and quality.