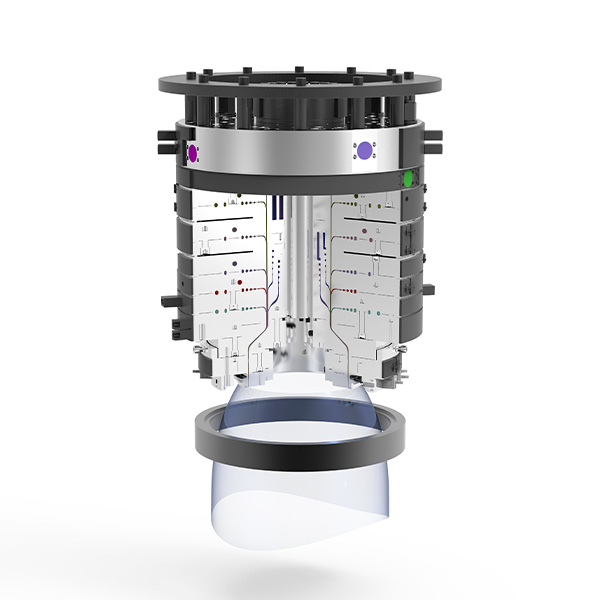

CHAOXIN uses its own flow channel simulation tech and multi-layer co-extrusion process to make sure the film thickness is even. With a temperature- and humidity-controlled workshop and European five-axis processing equipment, they use special alloy steel to make high-precision, long-lasting professional die heads.

1. Central feed, side feed, flat stacking, flat taper stacking, different structures to choose from.

2. Standard die diameter φ500- φ 1000mm, fluid surface roughness Ra0.025, roundness error within ±0.01mm.

3. Customizable three-layer, five-layer, seven-layer, nine-layer, eleven-layer, and other specifications.